AIR CONDITIONING, AND VENTILATION

Fresh, clean air for men and machines

The needs of the process and the well-being of the workers require adequate control of the temperature, humidity and ventilation of the production rooms and technical environments.

CST specializes in finding innovative solutions to manage even those problems that seemed insoluble, always with an eye to saving and recovering resources.

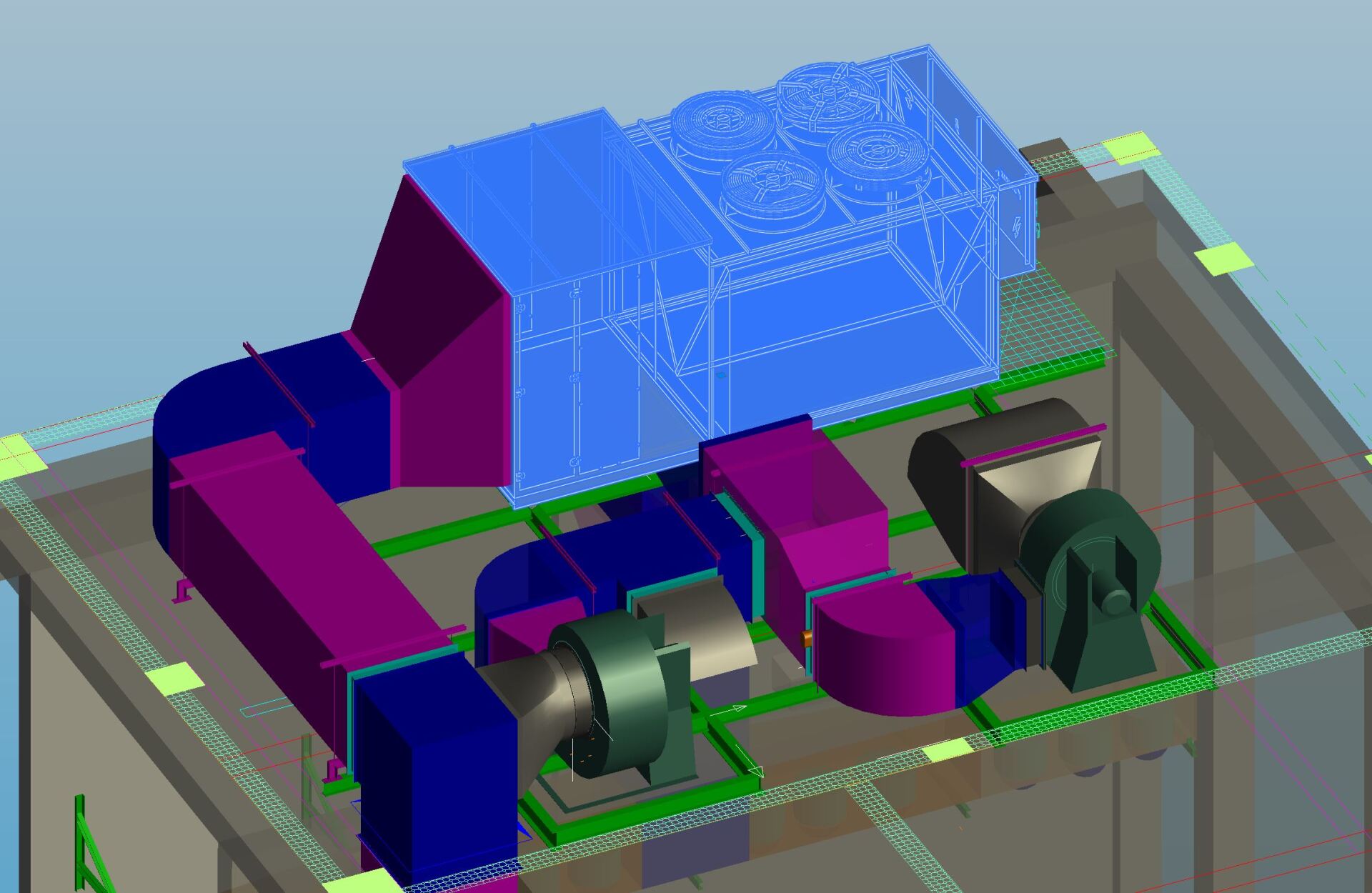

THE RIGHT SOURCES FOR THE RIGHT USE

Often a correct definition of the available sources makes it possible to implement solutions that would otherwise be prohibitive in terms of plant and operating costs. CST manufactures systems with recovery systems, traditional air conditioning (chillers, heat pumps), absorption systems (hot water or steam) and hybrid solutions that also exploit free-cooling. CST is also specialized in the design of ad hoc distribution systems that allow to contain the volumes to be treated, focusing the result on real needs.

Cooling of electrical panels

Whether distributed in the field or grouped within electrical substations, the drives represent the heart of the production plants.

Adequate cooling of the electrical panels is necessary to avoid out of service and significantly increase the life of the components.

CST creates targeted solutions for all situations, as evidenced by the numerous installations in Italy and abroad.

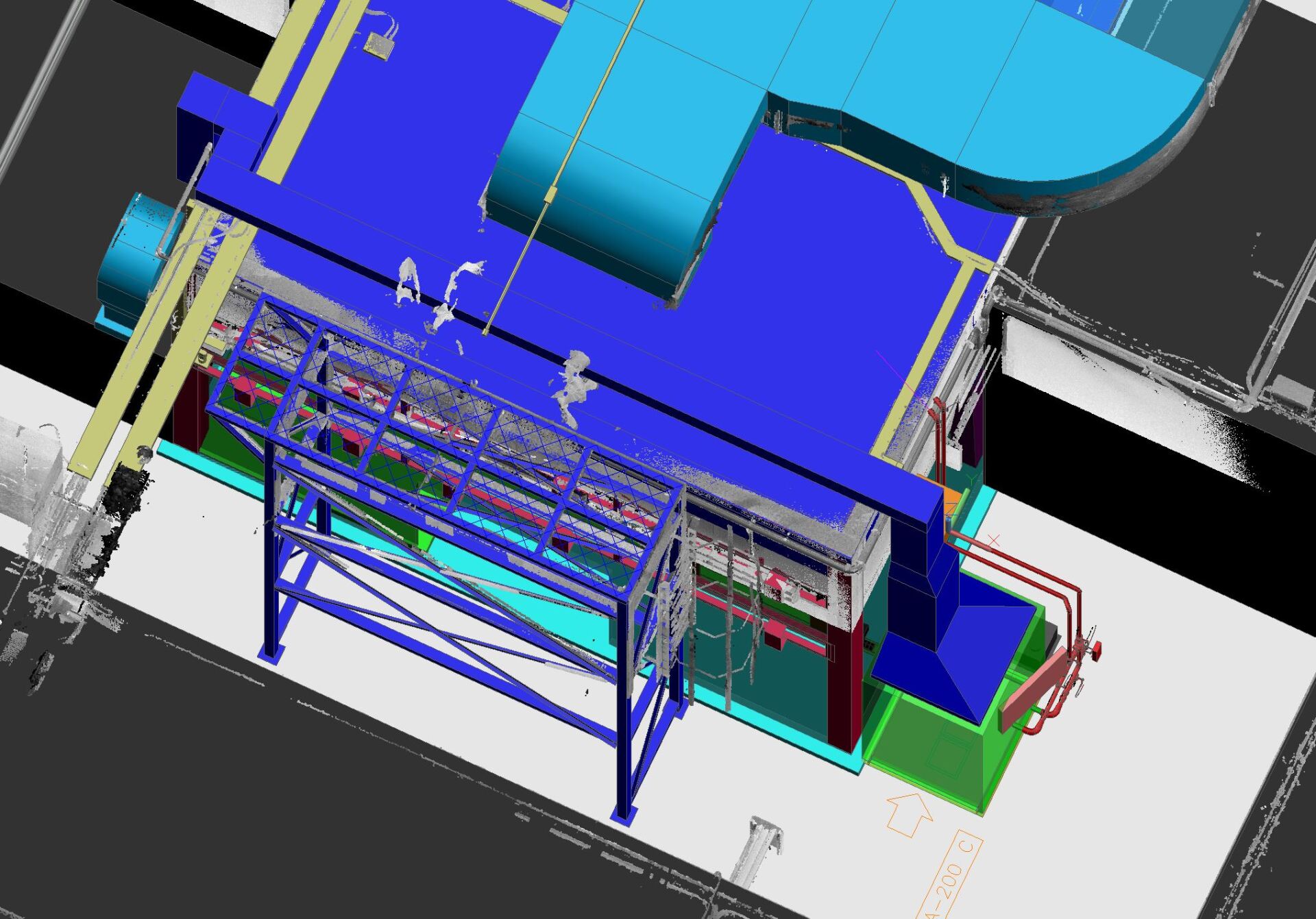

Sheds and workplaces

Ambient air conditions are often a crucial element for production needs.

The very large volumes represent a challenge for the correct sizing and optimization of heat exchanges, fans and distribution pipes.