WATER PURIFICATION

Water is the most precious commodity

The global context pushes more and more towards a reduction in the consumption of all resources, in the first place of water.

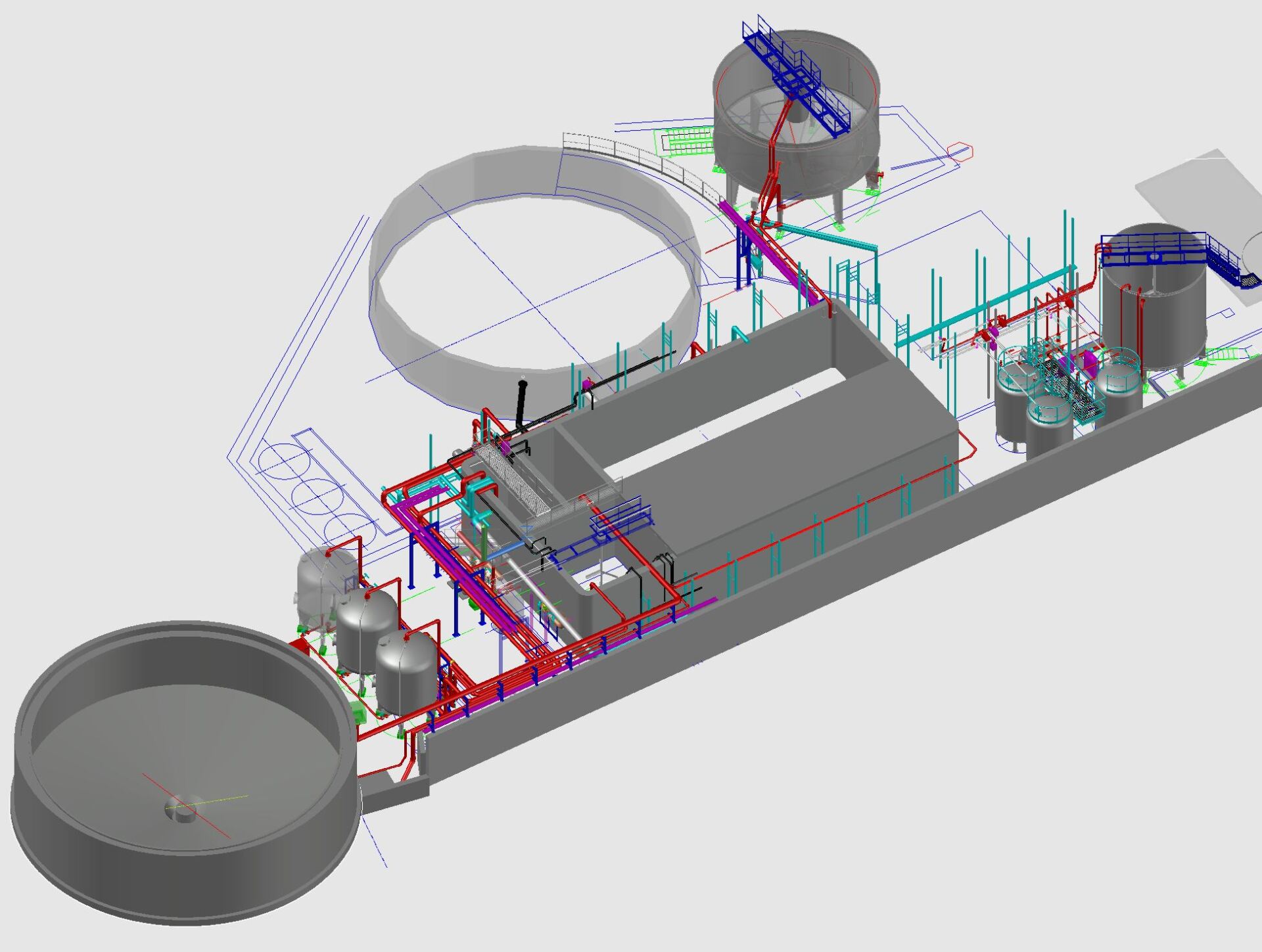

The closure of the cycles and the cascade recovery require the application of the best technologies for the treatment of incoming water and the purification and recovery of wastewater and groundwater.

The key is recovery

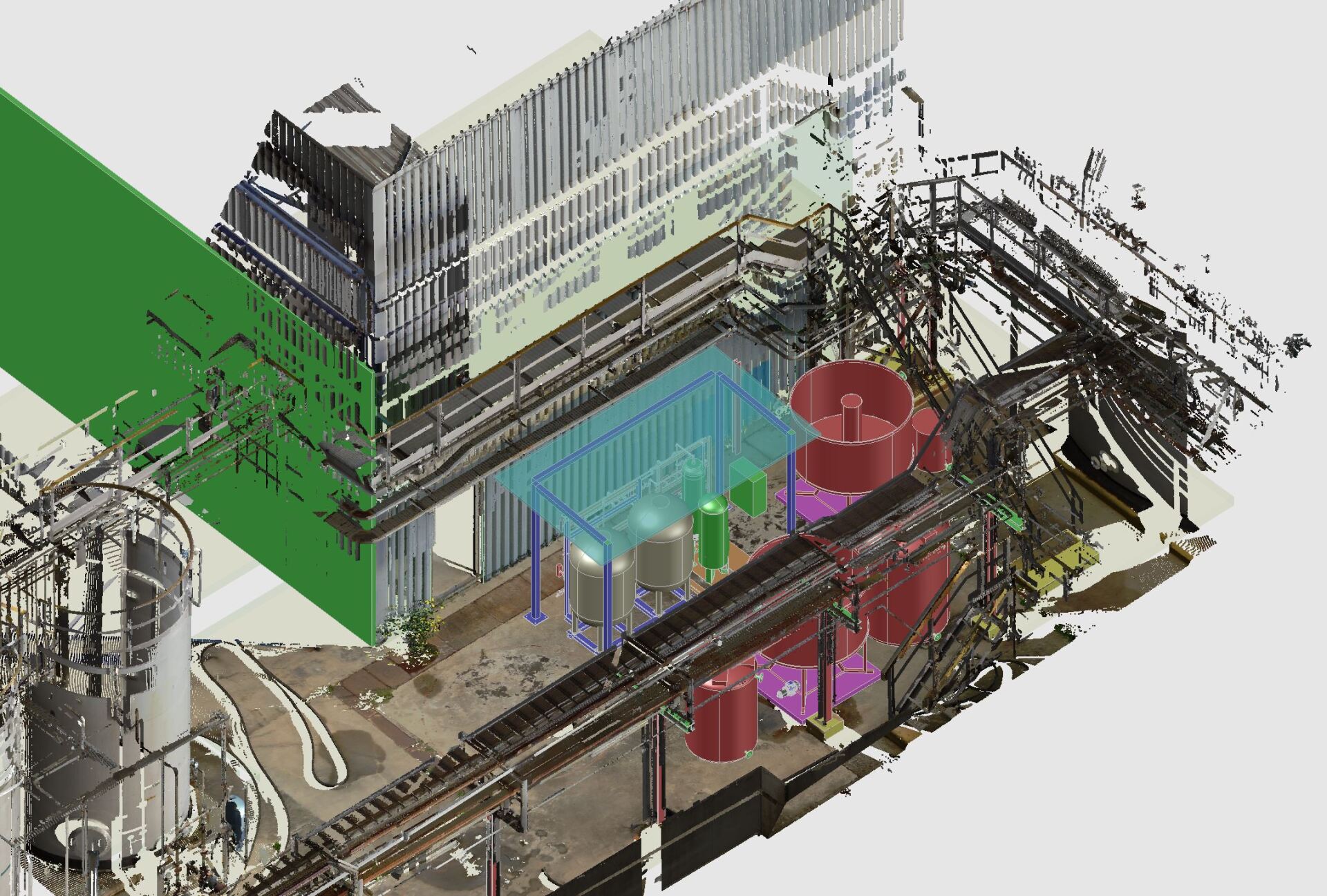

CST has always not limited itself to proposing specific solutions for water treatment (whether primary or effluent), but its vocation is to analyze the water cycle in a company and find solutions, often not so evident, for the reduction of consumption and discharges through optimization and recovery.

Tradition and innovation

Alongside proven technologies of chemical-physical clarification, filtration on various media, resin demineralization and reverse osmosis, it is precisely the technology of membranes that can change the water balance of a company.

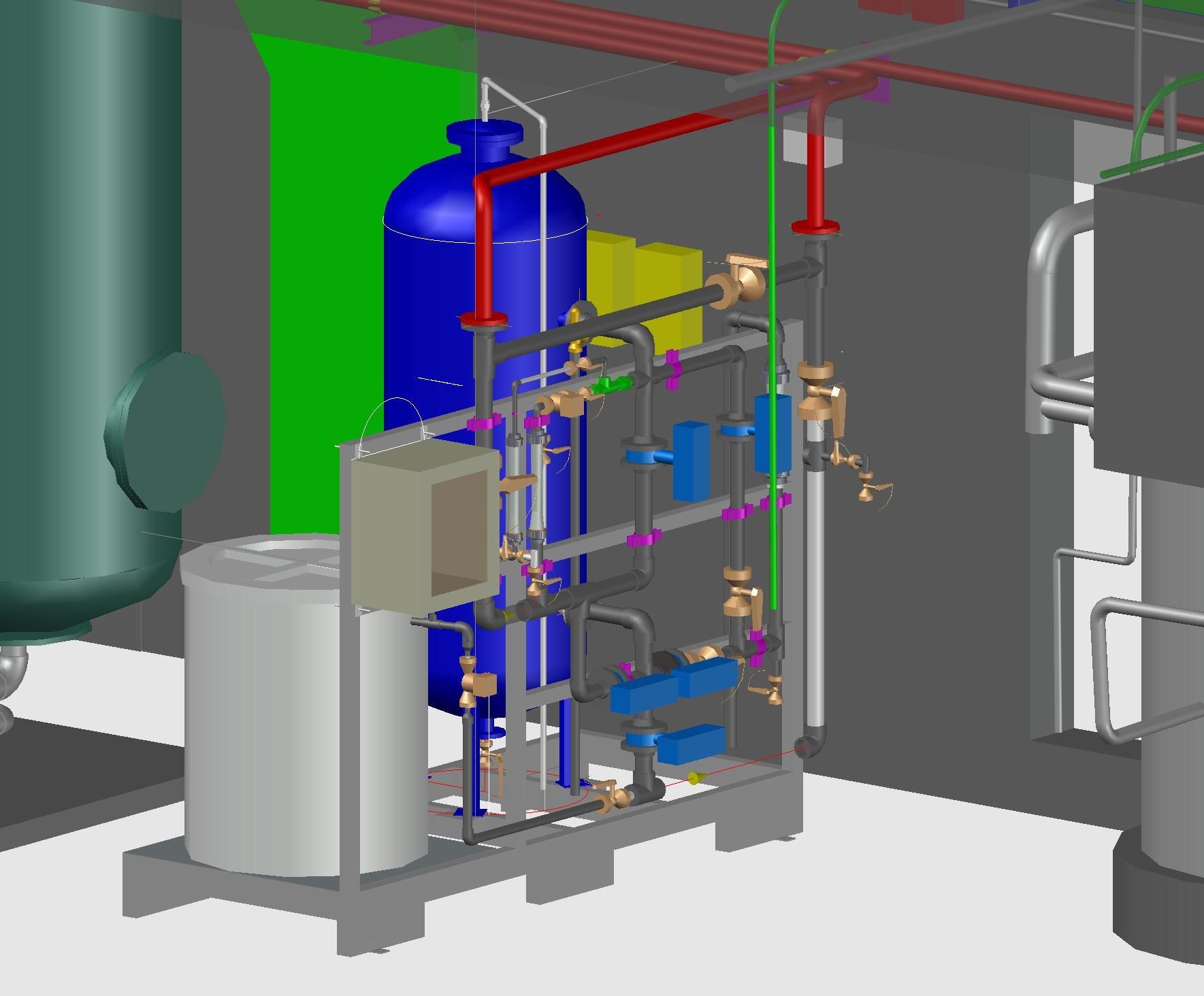

CST collaborates with the main world distributor of membranes for ultrafiltration, osmosis and EDI to size and build fixed and skid systems, including mobile ones.

CST also carries out pilot tests on new technologies in the field of wastewater treatment to offer a range of state-of-the-art solutions to its customers.

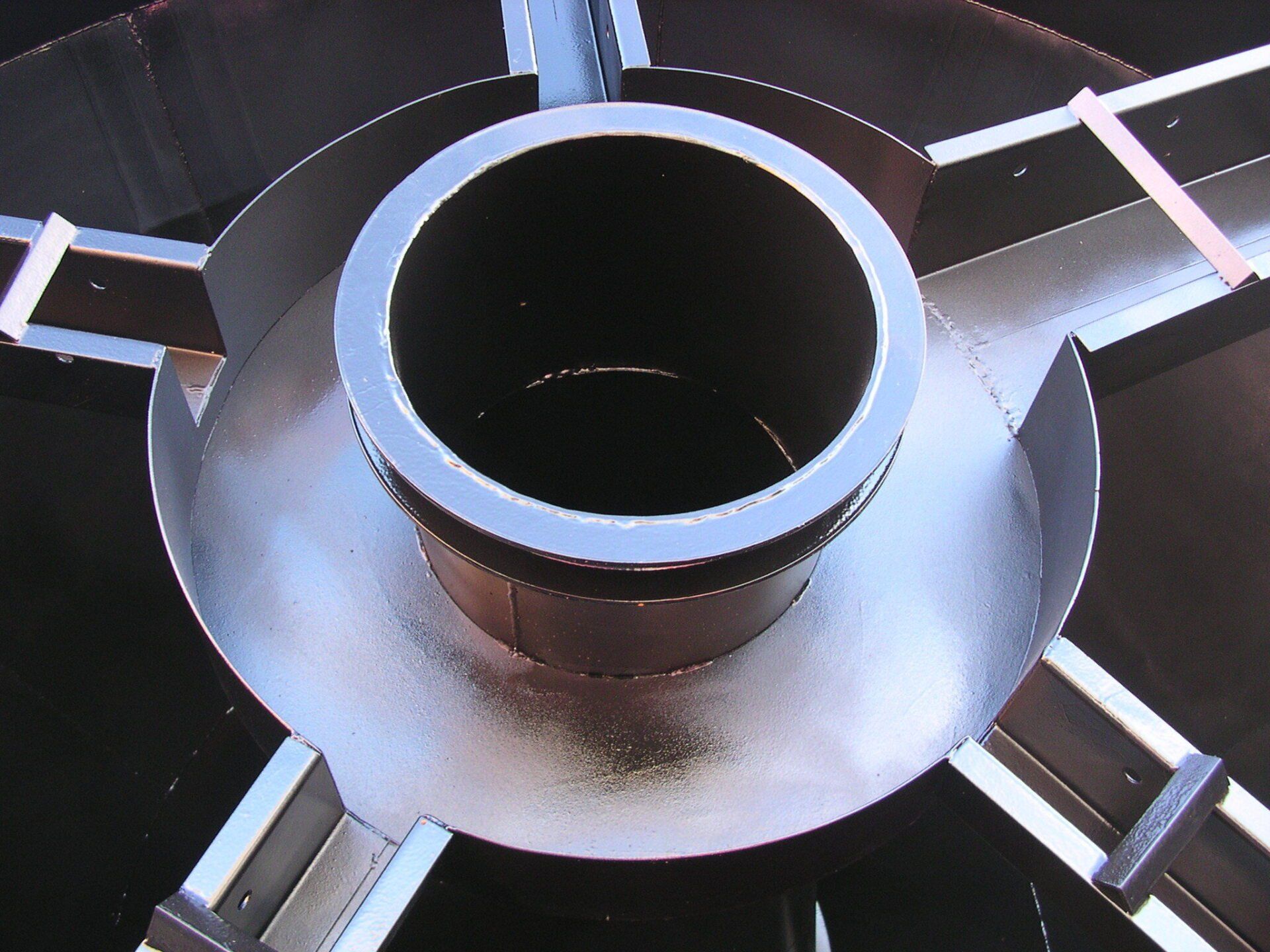

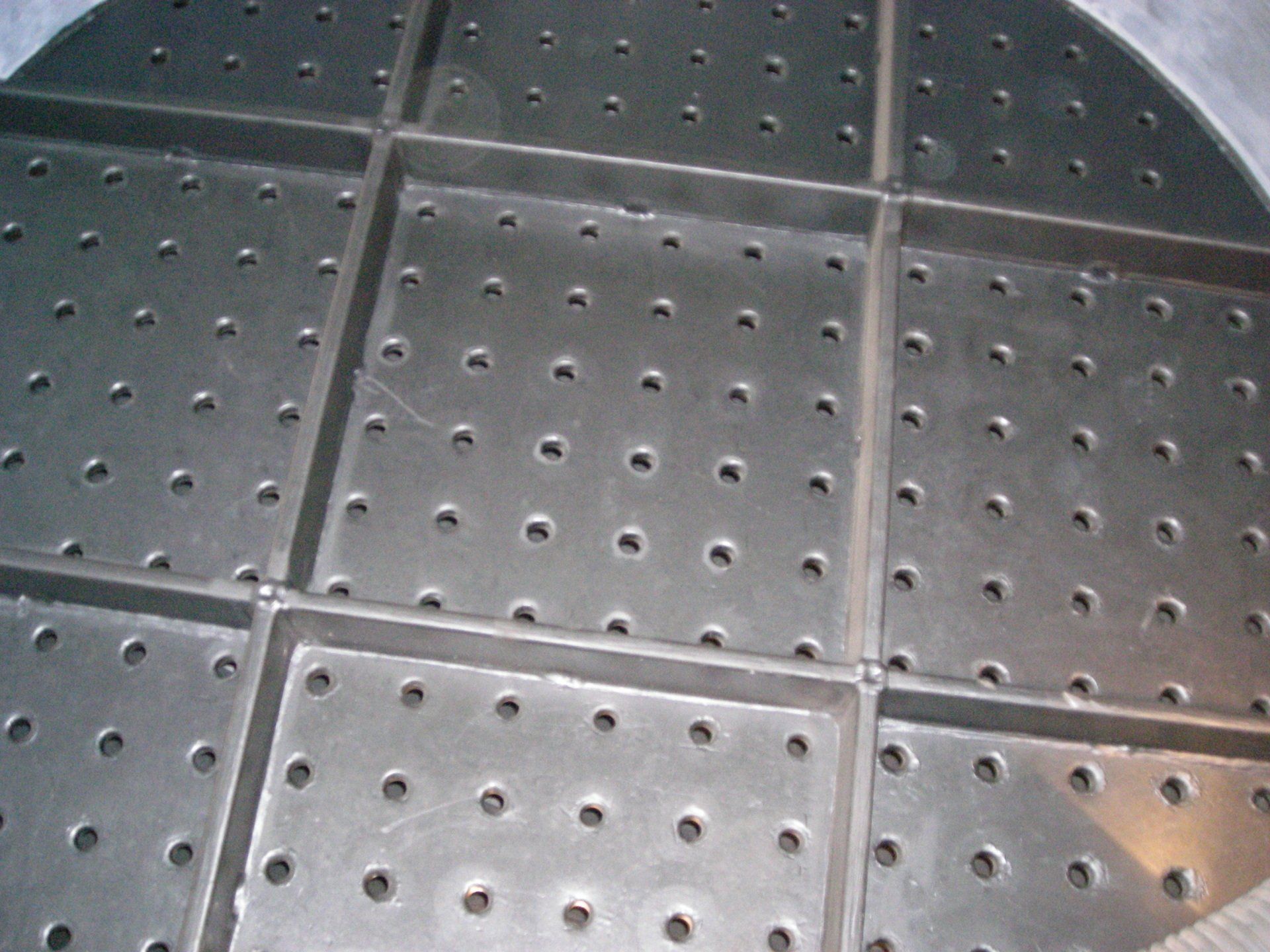

Filtration and clarification

Solid / liquid separations are fundamental operations for water treatment and can be carried out with various measures:

- static circular clarifiers lamella pack refiners longitudinal clarifiers dissolved air flotators (DAF) induced air flotators (IAF) multi-layer pressure sand filters activated carbon filters (GAC)

CST is able to identify the best technology for the individual case

Desolation

The separation of free and emulsified oils is often a difficult problem to solve, especially due to the discontinuity of operating conditions. Usually it deals with the use of:

- dissolved air floaters (DAF) induced air floaters (IAF) sediment - static floaters with lamellar packs

Based on the needs of the individual case, the optimal solution is identified.

Chemical oxidation and conditioning

The dosage of chemicals is often essential for obtaining the best performance of a plant, so much so that the lack of chemical dosage is one of the most frequent causes of malfunctioning of a water treatment plant.

CST has gained a long experience in the chemical treatment of water, so it is able to provide devices and systems capable of maximizing the reliability and safety of the process, for example through:

- selection of chemicals in the laboratory (jar test) supply of pre-assembled skids for chemical dosing use of double wall lines, protection screens, devices to prevent the incorrect mixing of chemicals during the transfer phase.

Demineralization

The use of ion exchange resins is gradually decreasing in industrial plants, especially due to the use of chemical products that affect both safety in the workplace and the environmental impact of the site. Think of sodium cycle resins for water softening, but also of acid and basic cycle ion exchange resins for total or selective demineralization of water.

Obviously there is a series of special cases in which this technology is still the best solution, without forgetting the need to maintain the systems already installed and still in efficient service.

CST is able to create and maintain demineralization systems with ion exchange resins.

Cooling

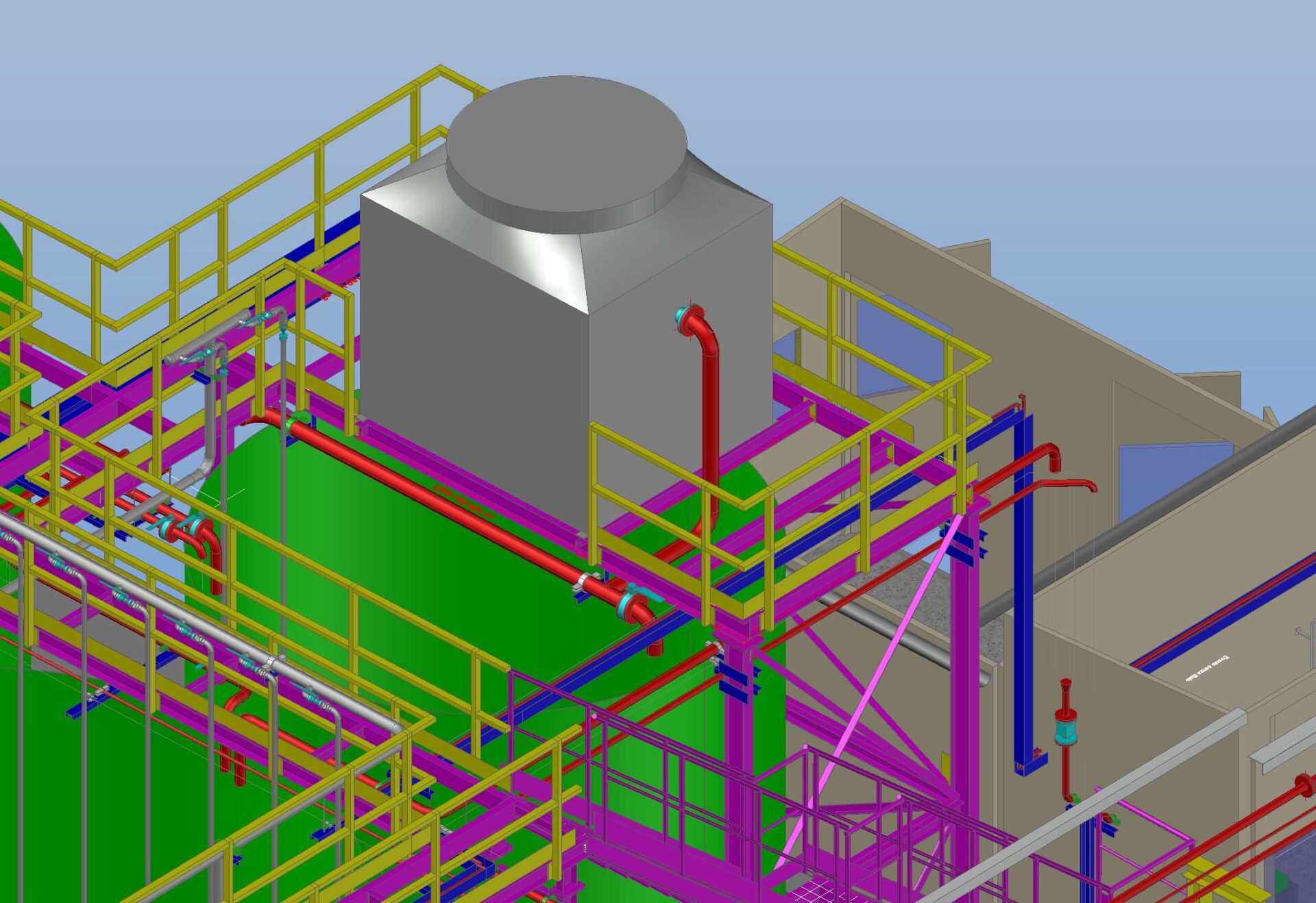

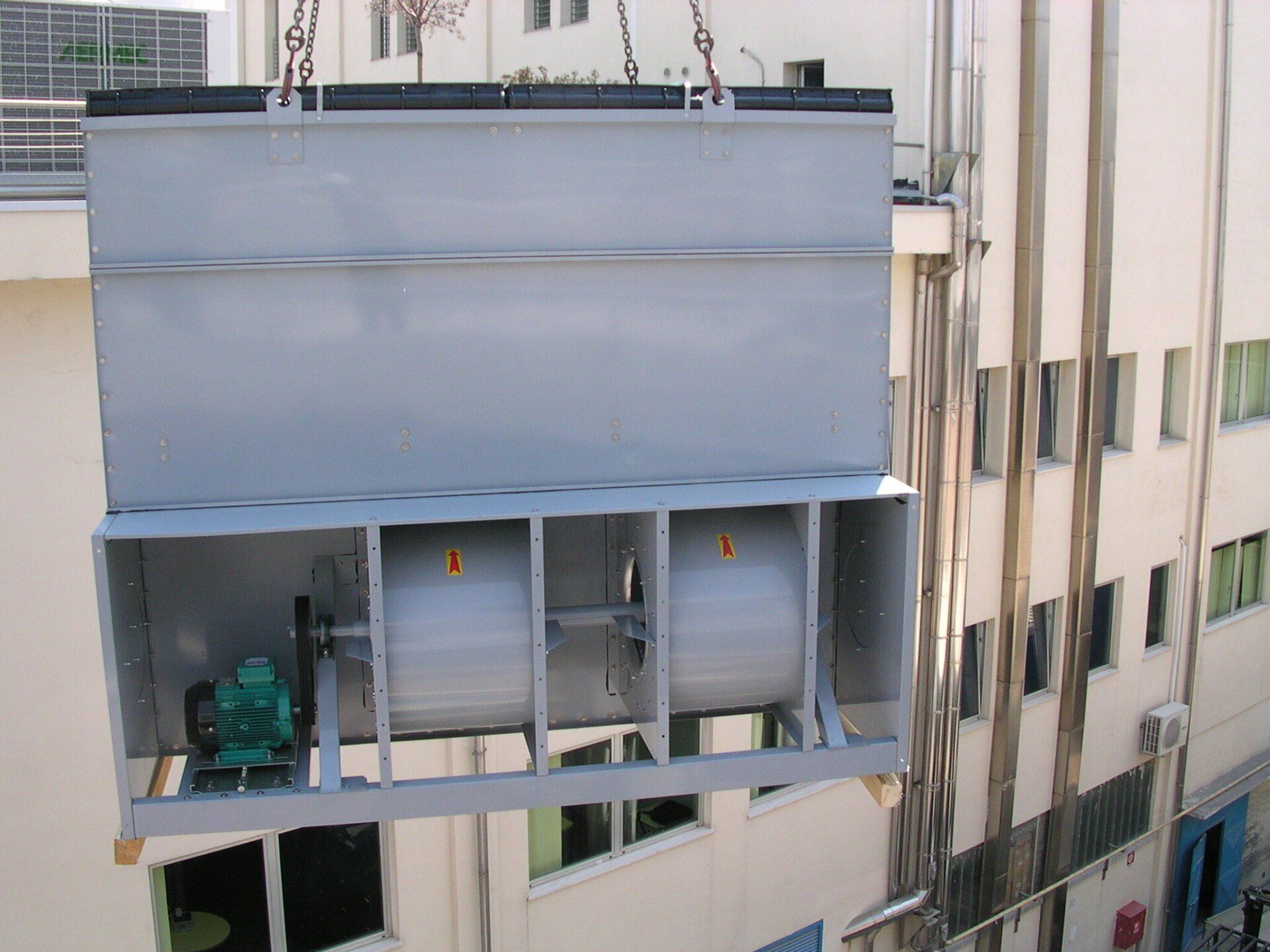

CST carries out the sizing and selection of an evaporative cooling tower through information and skills that refer to a series of specific boundary conditions for the individual case, including:

- characteristics of refrigerants type of make-up water (eg waste water reuse) availability of spaces

Biological and MBR plants

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

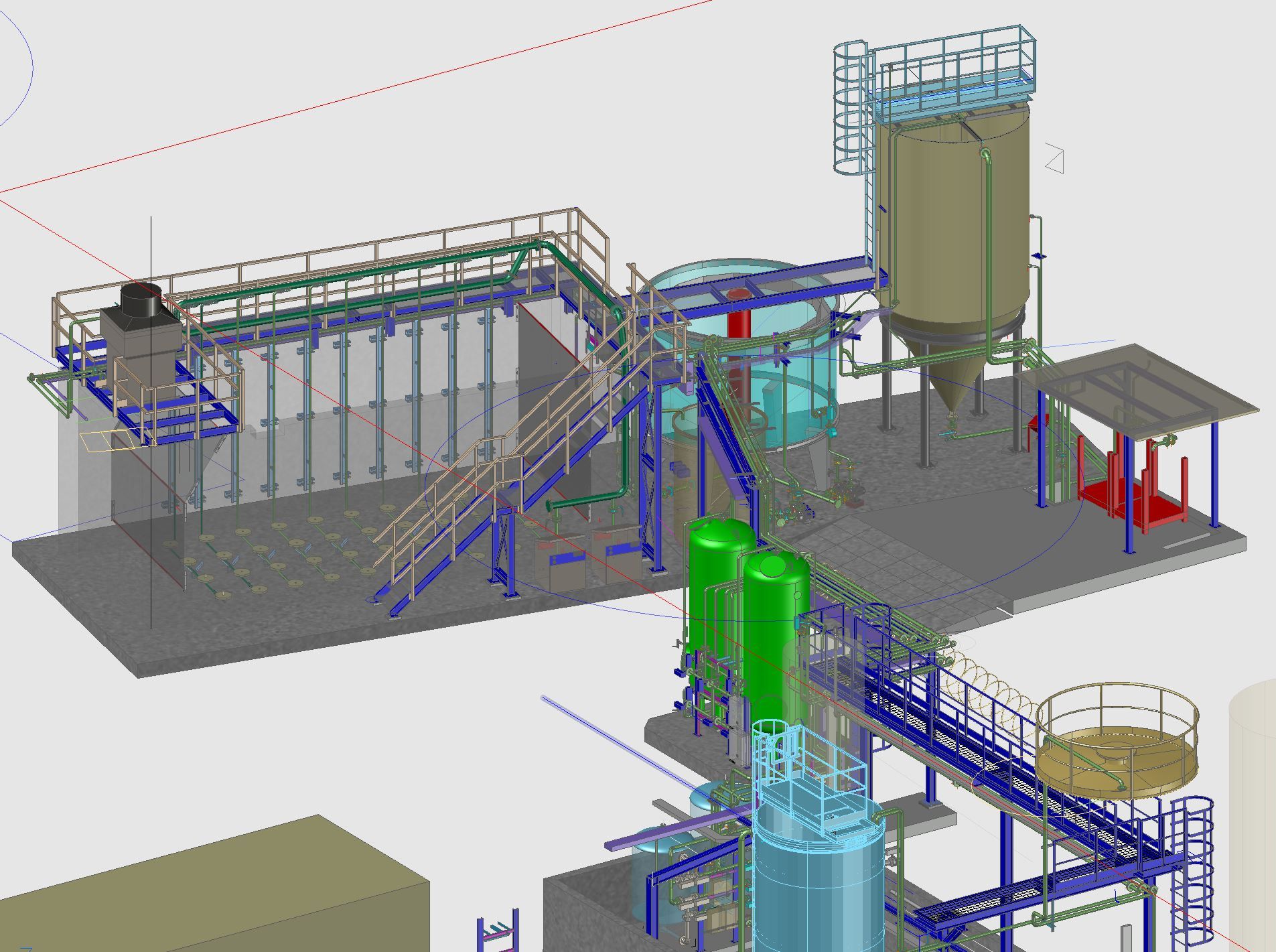

Ground water treatment

CST has developed significant experience in the field of "pump and treat" systems for groundwater containing various types of pollutants:

- organic solvents inorganic compounds

In many cases, through the study of the customer's water network, it was possible to reuse the treated water in the production process, obtaining evident advantages from both an authorization and image point of view.